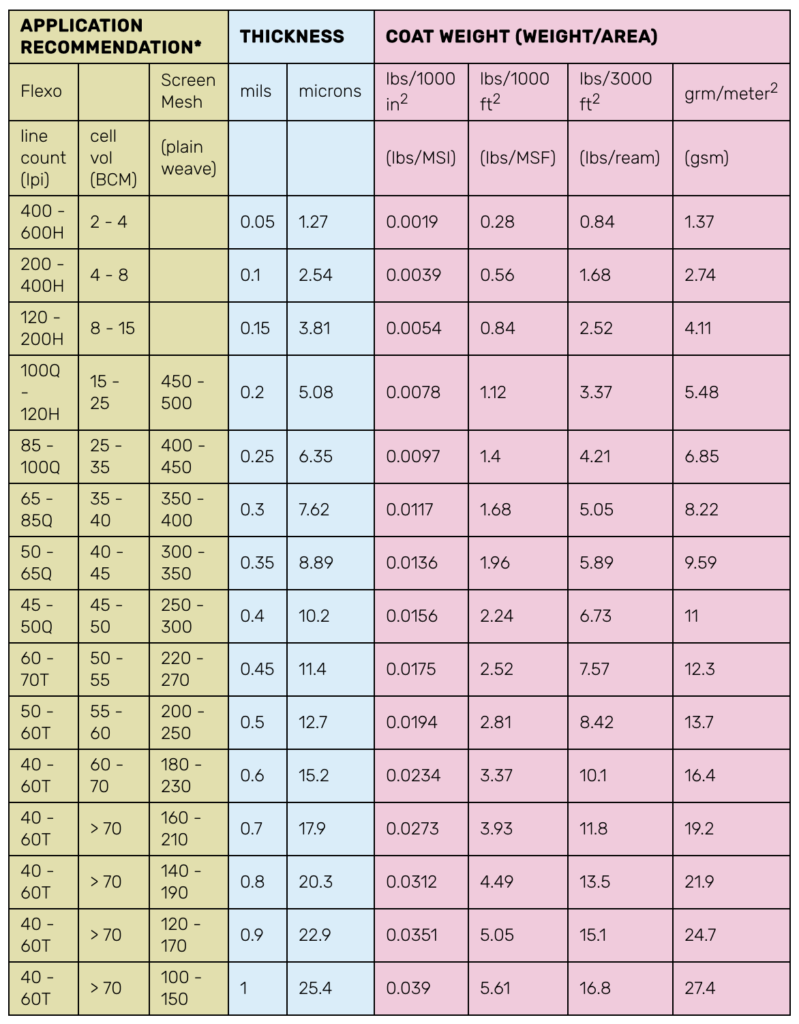

Coating Thickness and Usage

(Assumes 9.0 lbs/gallon and 100% Solids Systems)

*Approximate only: depends on transfer efficiency, coating rheology, and other equipment setup factors

| Application Recommendation* |

Thickness |

Coat Weight (weight/area) |

| Flexo |

|

Screen Mesh |

mils |

microns |

lbs/1000 in2 |

lbs/1000 ft2 |

lbs/3000 ft2 |

grm/meter2 |

| line count (lpi) |

cell vol (BCM) |

(plain weave) |

|

|

(lbs/MSI) |

(lbs/MSF) |

(lbs/ream) |

(gsm) |

| 400 - 600H |

2 - 4 |

|

0.05 |

1.27 |

0.0019 |

0.28 |

0.84 |

1.37 |

| 200 - 400H |

4 - 8 |

|

0.1 |

2.54 |

0.0039 |

0.56 |

1.68 |

2.74 |

| 120 - 200H |

8 - 15 |

|

0.15 |

3.81 |

0.0054 |

0.84 |

2.52 |

4.11 |

| 100Q - 120H |

15 - 25 |

450 - 500 |

0.2 |

5.08 |

0.0078 |

1.12 |

3.37 |

5.48 |

| 85 - 100Q |

25 - 35 |

400 - 450 |

0.25 |

6.35 |

0.0097 |

1.4 |

4.21 |

6.85 |

| 65 - 85Q |

35 - 40 |

350 - 400 |

0.3 |

7.62 |

0.0117 |

1.68 |

5.05 |

8.22 |

| 50 - 65Q |

40 - 45 |

300 - 350 |

0.35 |

8.89 |

0.0136 |

1.96 |

5.89 |

9.59 |

| 45 - 50Q |

45 - 50 |

250 - 300 |

0.4 |

10.2 |

0.0156 |

2.24 |

6.73 |

11 |

| 60 - 70T |

50 - 55 |

220 - 270 |

0.45 |

11.4 |

0.0175 |

2.52 |

7.57 |

12.3 |

| 50 - 60T |

55 - 60 |

200 - 250 |

0.5 |

12.7 |

0.0194 |

2.81 |

8.42 |

13.7 |

| 40 - 60T |

60 - 70 |

180 - 230 |

0.6 |

15.2 |

0.0234 |

3.37 |

10.1 |

16.4 |

| 40 - 60T |

> 70 |

160 - 210 |

0.7 |

17.9 |

0.0273 |

3.93 |

11.8 |

19.2 |

| 40 - 60T |

> 70 |

140 - 190 |

0.8 |

20.3 |

0.0312 |

4.49 |

13.5 |

21.9 |

| 40 - 60T |

> 70 |

120 - 170 |

0.9 |

22.9 |

0.0351 |

5.05 |

15.1 |

24.7 |

| 40 - 60T |

> 70 |

100 - 150 |

1 |

25.4 |

0.039 |

5.61 |

16.8 |

27.4 |

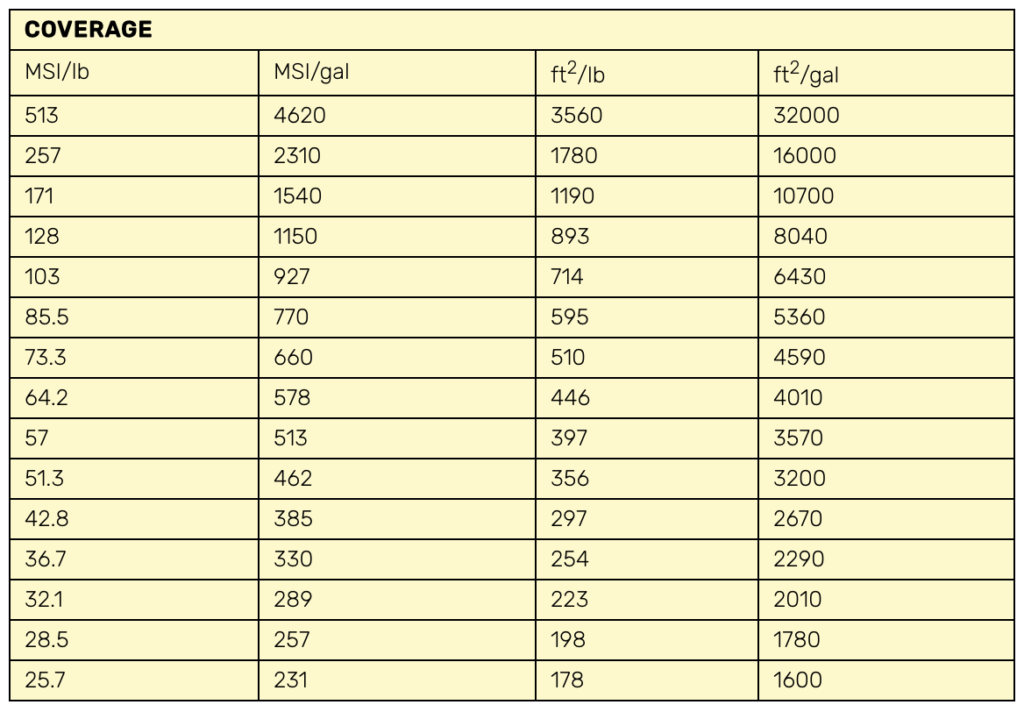

| Coverage |

| MSI/lb |

MSI/gal |

ft2/lb |

ft2/gal |

| 513 |

4620 |

3560 |

32000 |

| 257 |

2310 |

1780 |

16000 |

| 171 |

1540 |

1190 |

10700 |

| 128 |

1150 |

893 |

8040 |

| 103 |

927 |

714 |

6430 |

| 85.5 |

770 |

595 |

5360 |

| 73.3 |

660 |

510 |

4590 |

| 64.2 |

578 |

446 |

4010 |

| 57 |

513 |

397 |

3570 |

| 51.3 |

462 |

356 |

3200 |

| 42.8 |

385 |

297 |

2670 |

| 36.7 |

330 |

254 |

2290 |

| 32.1 |

289 |

223 |

2010 |

| 28.5 |

257 |

198 |

1780 |

| 25.7 |

231 |

178 |

1600 |